FrSky Xact 6500 Series Brushless High-Voltage Servos

OVERVIEW

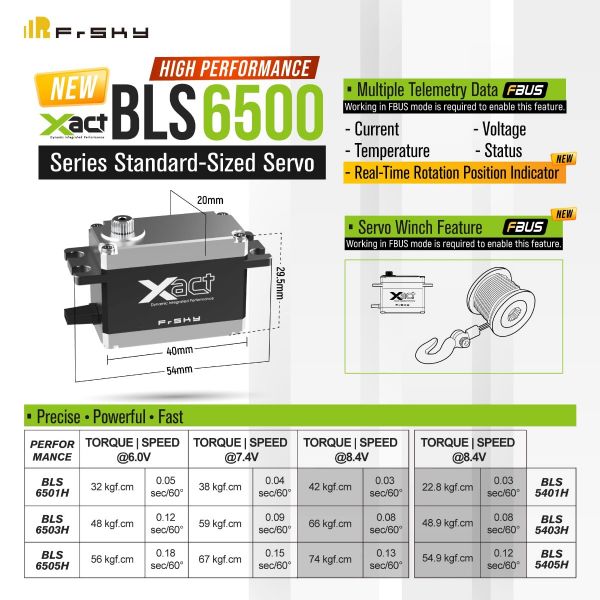

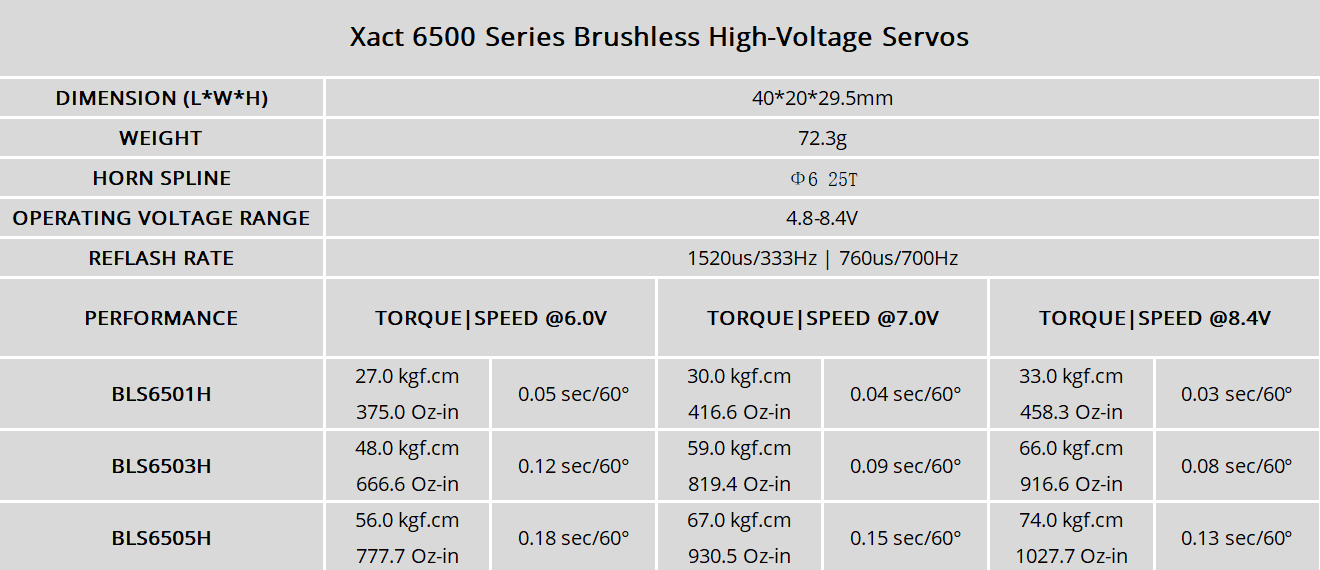

The Xact series brushless servos utilize a fully CNC machined aluminum protective case and benefit from metal gears and precise hall-sensor builds. These high-voltage servos can support up to 8.4V and offer fast response and powerful torque performance. These servos offer different form factors and deliver matched performance to fit different model types, so they are ideally matched to models especially where power, reliability, and precision are required.

Telemetry and Configurations (FBUS mode)

Working with the FBUS protocol features real-time telemetry data (such as current, voltage, and rotation position indicator, etc.), all the telemetry data can be achieved and read directly on the radio this way. Furthermore, configurable parameters like the servo center point and travel degrees can be set easily with flexibility on FrSky radios by the integration tool, and are also accessible by the PC configuration tool (ServoConfiguration).

Servo Winch (FBUS mode)

The servo winch feature is another main point using FBUS mode with 6500 series servos, no additional controller system is needed. Users can decide whether the servo arm rotates clockwise or counterclockwise continuously, and can even fine-tune the speed of its rotation.

FEATURES

● Supports FBUS, SBUS, and PWM protocol

● High durability with metal gear and all-aluminum CNC machined protective case

● 8.4V high voltage capable operation with FAST response and POWERFUL torque performance

● Built-in dual ball-bearing with PRECISE hall sensor

● Supports telemetry feedback (FBUS mode)

- Current / Voltage / Temperature / Status

- Rotation Position Indicator

● Servo winch feature (FBUS mode)

- Winch controller capable, no additional controller needed

- Compatible with Φ6 25T winch spools

(The winch accessories, such as spools, line, hook, etc. need to be purchased separately.)

- Configurable by ETHOS integration tool or PC ServoConfiguration Tool

● Updatable firmware ensures superior performance